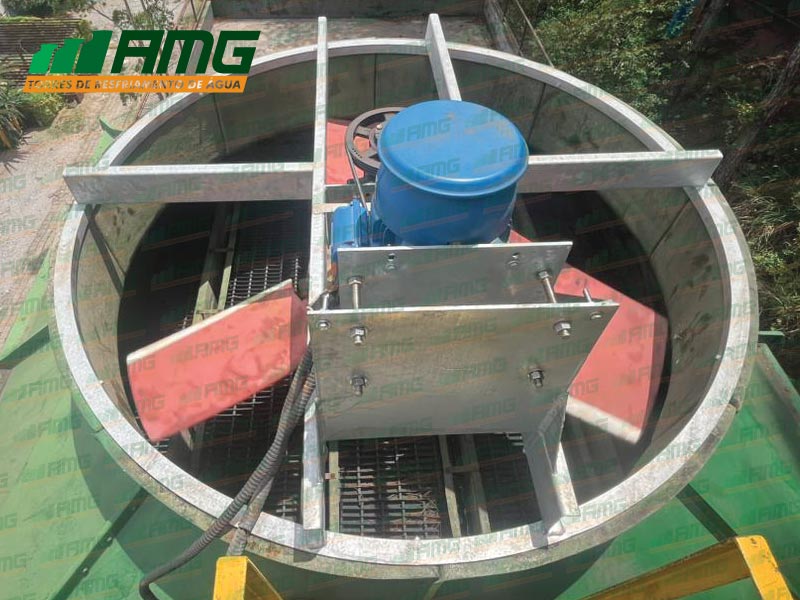

Cooling tower rim maintenance engine support

Cooling tower maintenance includes replacing the motor support ring.

Cooling tower maintenance is essential to ensure efficient thermal performance, energy savings, and prevent structural or biological failures (such as algae and bacteria growth).

Here is a complete summary of the main types of maintenance, steps, and technical recommendations:

Types of Maintenance

a) Preventive

Performed periodically to prevent failures and loss of efficiency.

Includes:

Cleaning the filler, mist eliminators, and basin.

Checking fan and motor vibrations.

Adjusting belts and bearings.

Water chemistry control (pH, alkalinity, hardness, chlorine).

Visual inspection for corrosion and obstructions.

b) Corrective

Performed after failures or poor performance occur, such as:

Replacing the motor, filler, nozzles, or eliminators.

Repairing leaks or seepage.

Replacing corroded components.

c) Predictive

Based on measurements and sensors:

Bearing vibration and temperature analysis.

Thermal performance monitoring (TAQ, TAF, TBU).

Client: Shopping Center.

Location: São Paulo/SP.